How Does an Automatic Peristaltic Pump Liquid Filling Machine Work?

01/01/2024

How an Automatic Multi Head Liquid Filling Machine Can Change Your Manufacturing Process

28/01/2024

Maximizing Your Liquid Filling Machine's Lifespan: 5 Essential Maintenance Tips

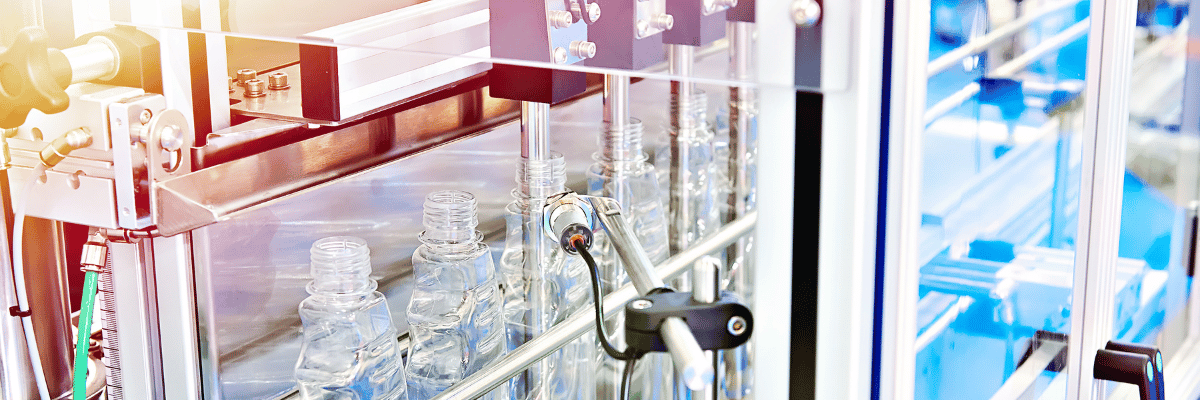

Liquid filling machines are essential machines in various industries, including pharmaceuticals, food and beverage, cosmetics, and chemicals. A well-maintained filling machine can save you time, money, and hassle in the long run. But how do you keep your liquid filling machine in top-notch condition? Siddhivinayak Industries is a leading Automatic Liquid Filling Machine Exporter in Ahmedabad, Gujarat, India. We manufacture all types of liquid filling machines like Automatic Volumetric Liquid Filling Machine, Semi Automatic Volumetric Liquid Filling Machine, Automatic Servo Gear Pump Liquid Filling Machine, Automatic Servo Piston Liquid Filling Machine, Automatic Overflow Liquid Filling Machine, Automatic Pneumatic Piston Liquid Filling Machine, Automatic Massflow Liquid Filling Machine, and Automatic Peristaltic Pump Liquid Filling Machine. As a leading Supplier of Liquid Filling Machines, we’ll share five essential maintenance tips that will help you maximize your liquid filling machine’s lifespan.

Importance of regular maintenance

First and foremost, regular maintenance helps prevent breakdowns and downtime. When your machine is down, you’re not producing, which can lead to lost revenue, missed deadlines, and unhappy customers. Regular maintenance can also improve efficiency and productivity by keeping your machine running at peak performance. Additionally, regular maintenance can help extend the life of your Automatic Volumetric Liquid Filling Machine, saving you money on repairs and replacements in the long run.

Essential maintenance tips

Cleaning and sanitation-

One of the most critical maintenance tasks for liquid filling machines is cleaning and sanitation. Filling machines handle food, beverage, and pharmaceutical products, so it’s essential to keep them clean and free of bacteria and other contaminants. Regular cleaning and sanitation can also prevent corrosion and damage to the machine. To clean Semi Automatic Volumetric Liquid Filling Machine, first, disconnect it from the power source and remove any product residue. Then, use a cleaning solution and a soft brush to scrub the machine’s surfaces thoroughly. Rinse with water and dry with a clean cloth. Finally, sanitize the machine with a food-grade sanitizer and let it dry completely before using it again.

Lubrication-

Another crucial maintenance task for the liquid filling machine is lubrication. Moving parts in the Automatic Servo Gear Pump Liquid Filling Machine needs proper lubrication to prevent wear and tear and ensure smooth operation. Use a high-quality lubricant and apply it sparingly to the designated lubrication points. Be sure to wipe away any excess lubricant to prevent buildup.

Calibration-

Calibration is essential to ensure the accuracy of the liquid filling machine. Over time, the machine’s sensors and other components can become misaligned, leading to inaccurate filling levels and wasted product. Regular calibration can prevent these issues and ensure consistent, reliable performance. Our Automatic Pneumatic Piston Liquid Filling Machine is fully sensors and touch screen.

Inspection and replacement of parts-

Regular inspection of the Automatic Overflow Liquid Filling Machine is crucial to identify and replace worn or damaged parts. Check the machine’s components regularly and replace any worn or damaged parts promptly. Follow our recommended replacement schedule.

Training and education for operators-

Finally, training and education for the Automatic Servo Piston Liquid Filling Machine operators are essential to ensure proper use and maintenance. Provide regular training and education opportunities for operators to keep them up to date on best practices and new technologies.

Siddhivinayak Industries is a reputed Exporter of Automatic Liquid Filling Machines in India. We have gained industry experience over the years and are highly dedicated to providing satisfactory products to customers. Apart from this, we are dedicated to constant quality improvement, which helps us to assist to take our company to new heights.