Introducing the Automatic Pneumatic Piston Liquid Filling Machine

27/10/2023

Boost Your Production Efficiency with a Semi Automatic Volumetric Liquid Filling Machine

25/12/2023

The Top 5 Benefits of Investing in an Automatic Massflow Liquid Filling Machine for Your Production Line

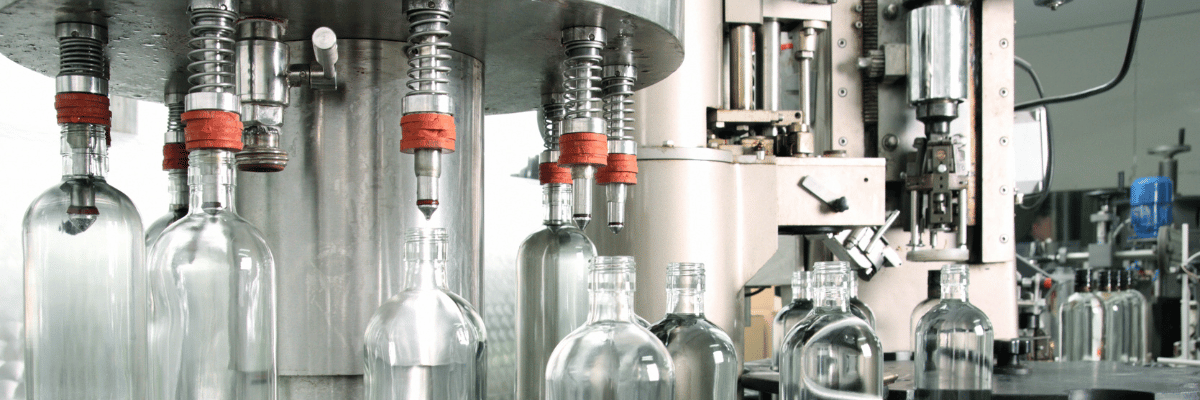

In the fast-paced world of industrial production, you know that efficiency and productivity are key to running a successful business. One way to achieve this is by investing in an automatic massflow liquid filling machine. We are a leading Automatic Massflow Liquid Filling Machine Manufacturer in Ahmedabad, Gujarat, India. Our machines are designed to streamline the filling process, making it faster, more accurate, and less manpower required. Not only do they increase production capacity, but they also improve product quality and consistency. In this blog, we’ll explore the top 5 benefits of investing in an automatic massflow liquid filling machine for your production line

- Increased efficiency and productivity

Efficiency and productivity are essential for any business, and an automatic massflow liquid filling machine can help you achieve both. With these filling machines, you can fill containers much faster than you would with manual filling, and you can do it with greater accuracy. This means that you can produce more products in less time, which can help you meet customer demand and increase profits.

In addition to increased speed and accuracy, automatic massflow liquid filling machines can also help you reduce errors. They use advanced sensors and controls to ensure that each container is filled to the correct level, which can help you avoid under-filling or over-filling.

- Consistent and accurate filling

Consistency is crucial for any product, and it’s particularly important for liquids. With an automatic massflow liquid filling machine, you can achieve consistent and accurate filling every time. Our machines are designed to maintain a consistent flow rate, which means that each container will be filled with the exact same amount of liquid.

In addition to consistent filling, these machines also offer precise filling. Automatic Multi Head Liquid Filling Machine uses advanced sensors and controls to measure the exact amount of liquid in each container, which can help you avoid waste and reduce costs. This is especially important for expensive or delicate liquids, where even a small amount of waste can be significant. An automatic massflow liquid filling machine is that it allows you to fill a wide range of container sizes and shapes. Our machines can be easily adjusted to accommodate different container sizes.

- Reduced waste and costs

By reducing errors and improving accuracy, these machines can help you avoid waste and reduce the cost of materials. This can be particularly beneficial for expensive or hard-to-find liquids. Another advantage of using these machines is that they can help you reduce labor costs. With an automatic massflow liquid filling machine, you can fill containers with just one or two people, freeing up your staff for other tasks.

Automatic massflow liquid filling machines can also help you save on maintenance costs. Our machines are designed to be durable and reliable, which means require less maintenance than manual filling machines.

- Improved safety and hygiene

Our machines are designed to be safe and easy to use, which can help you avoid accidents and injuries. We also use advanced sensors and controls to ensure that each container is filled to the correct level, which can help you avoid spills and leaks.

In addition to improved safety, automatic massflow liquid filling machines can also help you maintain hygiene standards. Our machines are designed to be easy to clean and sanitize, which can help you avoid contamination. This is particularly important for food and beverage production, where hygiene is critical.

- Versatility and Flexibility

An Liquid Filling Machine offers versatility and flexibility in handling different types of liquids and containers. The machine can accommodate a wide range of liquid viscosities, from watery solutions to thick gels, without compromising accuracy. Additionally, it supports various container shapes and sizes, allowing you to fill different packaging formats with ease. This adaptability makes the machine ideal for businesses dealing with multiple product variations and packaging requirements.

Siddhivinayak Industries is a leading Automatic Massflow Liquid Filling Machine Supplier in Ahmedabad, dedicated to providing innovative and high-quality packaging solutions to customers worldwide. Investing in our automatic massflow liquid filling machine can provide a wide range of benefits for any business that needs to fill containers with liquid products. From increased efficiency and productivity to improved product quality and consistency, Our machines can help you stay ahead of the competition and achieve your business goals.

FAQS-

- How fast can these machines fill containers?

Automatic massflow filling machines can fill containers at very high speeds, typically up to 300 containers per minute depending on the container size. - Can the filling machine accommodate different container shapes and sizes?

Yes, an advantage of these fillers is their versatility. With quick change tooling, they can easily handle a wide variety of container shapes, sizes, and openings. - How fast can these machines fill containers?

Automatic massflow filling machines can fill containers at very high speeds, typically up to 300 containers per minute depending on the container size.